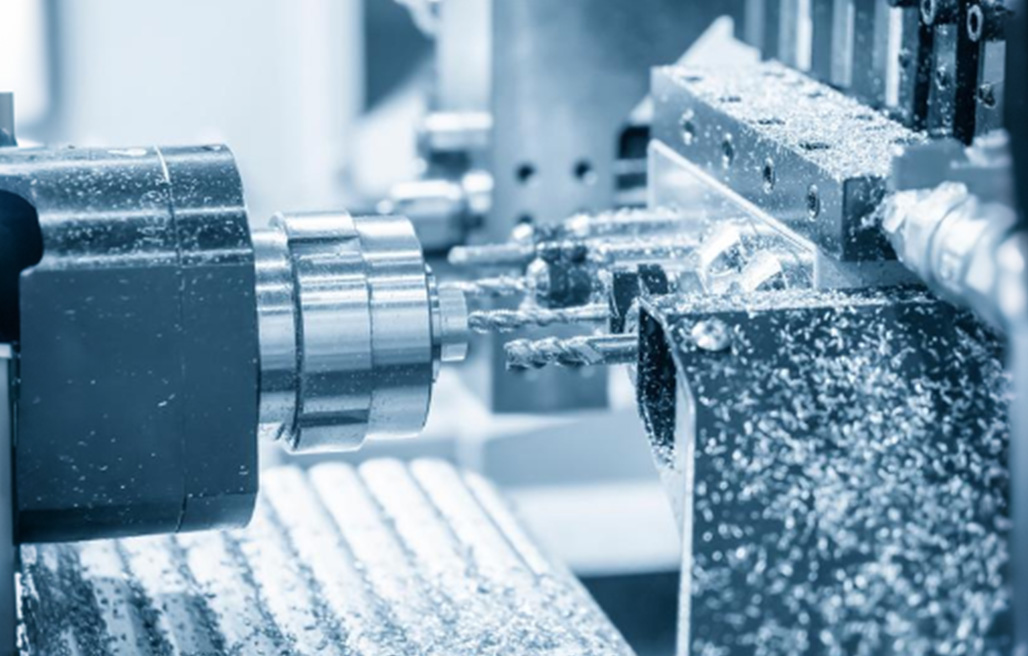

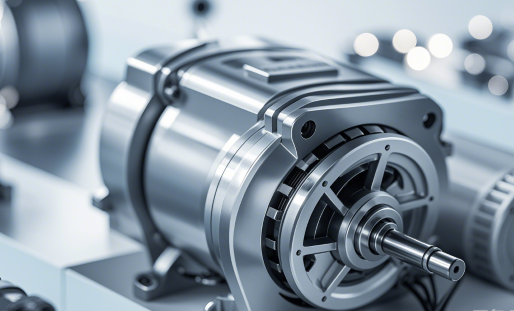

Servo Motor

Servo motors, as the core components of industrial automation, are types of motors capable of precise control, primarily used in applications requiring high-precision positioning and speed control. Time Vision Technology ensures that the motors maintain optimal performance in dynamically changing work environments by providing high-resolution position feedback, intelligent compensation algorithms, high-speed data processing, and precise encoding technologies for servo motors. This, in turn, enhances the efficiency and reliability of the entire system.

-

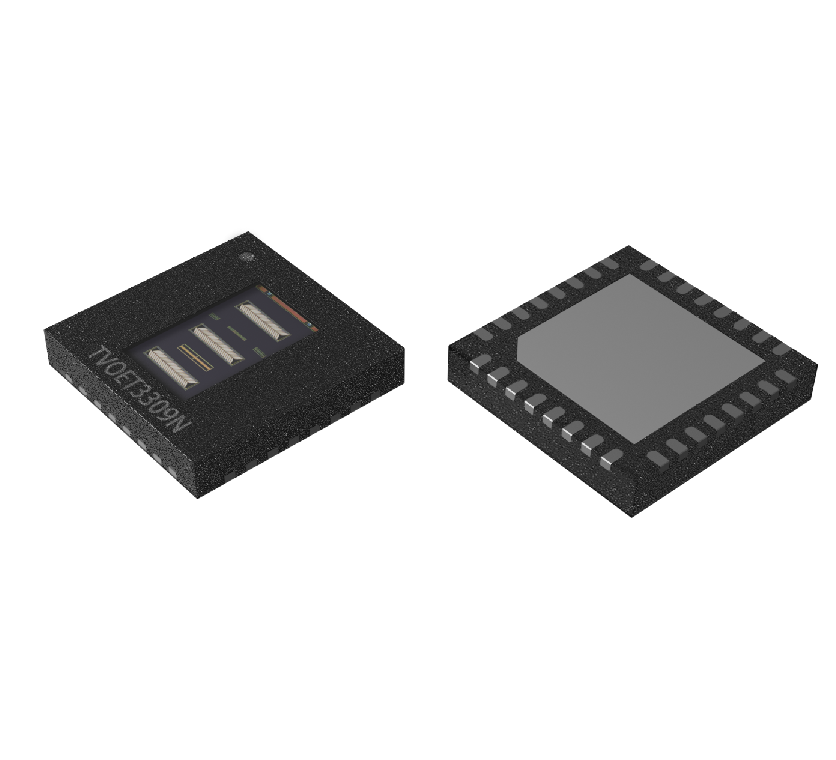

01

Strong System Rigidity

Real-time high-resolution position feedback, with a resolution of up to 26 bits, ensures precise and accurate motion control of the motor even under high-intensity dynamic loads. Its fast response characteristics enhance the rigidity and stability of the system, allowing the motor to maintain extremely high control precision even under complex operating conditions.

-

02

Suppress Rate Fluctuations

The intelligent compensation algorithm within the optical encoder chip effectively reduces rate fluctuations, ensuring the smoothness and stability of motor operation. Through precise speed adjustments, it can significantly reduce speed inconsistencies caused by external disturbances or internal changes, thereby improving work efficiency and reducing energy consumption.

-

03

Balance Between Speed and Precision

High-speed data processing capabilities and precise encoding technology enable the motor to maintain excellent positioning accuracy even at high rotational speeds, achieving the optimal balance between speed and precision. This meets the demanding performance requirements of industrial applications with stringent standards.

-

04

Environmental Adaptability

Ensuring consistent high performance in various working environments, it can operate stably within a wide temperature range of -40℃ to 150℃, significantly enhancing the system's reliability and long-term stability, and adapting to various harsh working conditions.